If you want to find the heart of modern industry, follow the smoke—there’s a reason the phrase "steel giant" still rings true. Giant in every sense: acreage, power consumption, workforce, and raw, mind-boggling output. But there’s an ongoing debate: Which one is the world’s biggest steel plant? The answer isn’t as straightforward as it sounds, because it’s not only about size on a map. It’s about the amount of steel it spits out each year, the footprint it leaves, and how it pretty much shapes the skylines not just near its own area, but often, entire countries far beyond its borders. And as the planet’s appetite for steel only grows—look around you, it’s in your car, your fridge, the bridges, the bikes, the cables—the monster mills behind this river of molten metal have had to keep up, innovate, and flex their muscle bigger than ever. Now, who’s at the top? Let’s check out the champion and what makes it impossible to ignore.

Meet the Steel Colossus: Baowu Steel Group’s Baoshan Base

If you’re searching for the king-sized beast of steel production, all roads lead to China, where the biggest steel plant in the world stands: Baowu Steel Group’s Baoshan Base in Shanghai. This site isn’t just massive. It’s an ongoing feat of human engineering. Baowu Steel Group isn’t some newcomer, either—they’ve been around since 1978, and today, Baoshan cranks out about 35 million metric tons of crude steel per year from this one sprawling complex. Think of that: If you melted down every car in New York, you’d still be nowhere near the yearly output.

The Baoshan site isn’t just one huge factory building but a collection of blast furnaces, rolling mills, coke plants, and a logistics network that could rival a small city’s infrastructure. It covers thousands of acres, with its ports and railways feeding a constant flow of iron ore and coal into its hungry maw. The area has its own fire station, hospitals, and even green belts because pollution and environmental impact are impossible to ignore. For perspective, the workforce involved numbers in the tens of thousands—roughly the same population as a big college town.

Let’s put those numbers into context. Here’s a quick comparison table showing the annual output of Baowu’s Baoshan site versus a few other famous steel giants:

| Steel Plant Name | Location | Annual Crude Steel Output (2024, million tons) |

|---|---|---|

| Baowu Steel (Baoshan Base) | Shanghai, China | 35 |

| ArcelorMittal Grande-Synthe | Dunkirk, France | 7.2 |

| POSCO Gwangyang Steelworks | Gwangyang, South Korea | 21 |

| Nippon Steel Kimitsu Works | Kimitsu, Japan | 10 |

Thirty-five million tons is a staggering figure. Baowu’s Baoshan doesn’t just make steel for rebar and pipes; its slabs, sheets, and coils end up in Tesla’s Shanghai gigafactory, bullet trains, gigantic ships, and even in those skyscrapers that seem to pop up overnight in Chinese metro jungles. They’ve pioneered high-end grades, green steel (think low-emission stuff), and products for quantum computing hardware. It’s not just about brute force; it’s about smart production, too.

Another wild fact: Baoshan is a leader in sustainability for steel, at least by the standards of an industry that’s known for being energy hungry. The plant recently invested over $1.5 billion in carbon capture tech, with goals to slash CO₂ emissions by a fifth before 2030. That means if you buy new appliances, EVs, or even stadium seats from leading brands, there’s a decent chance you’re indirectly connected to this epicenter of global steel.

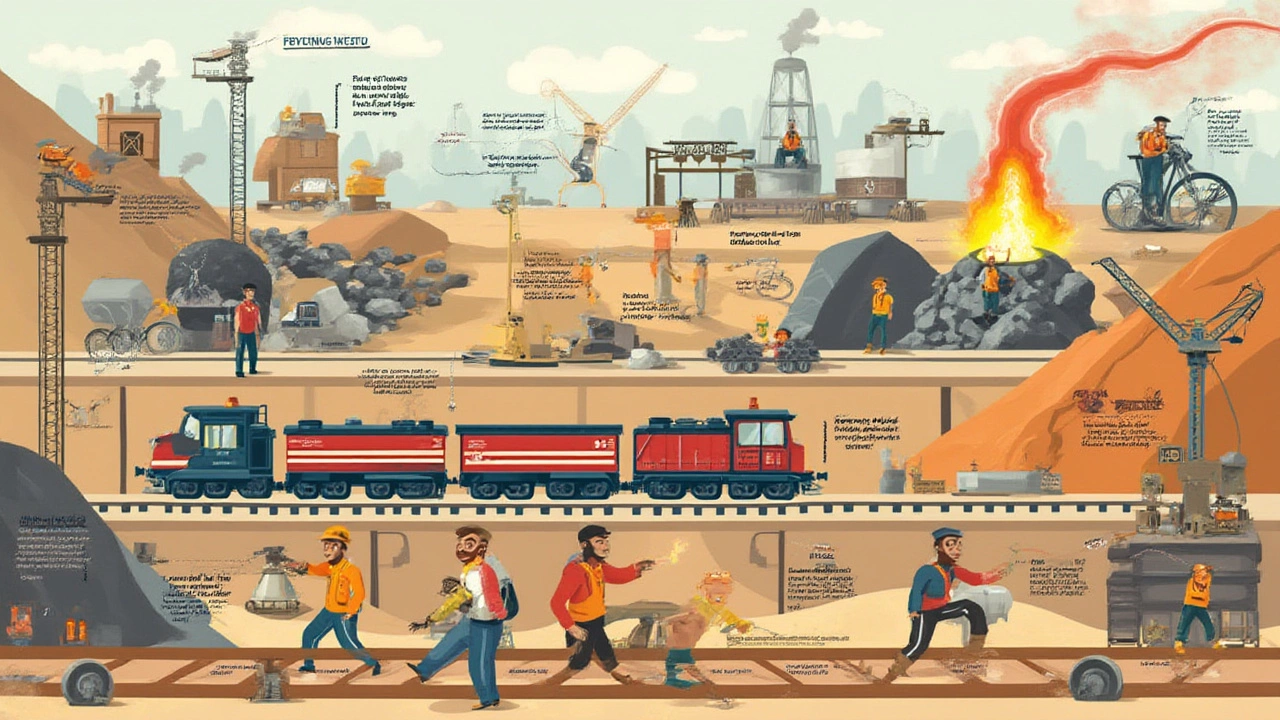

How the Largest Steel Plants Operate: From Ore to Output

If you walked into Baoshan (assuming they let random strangers in, which they won’t!), you’d see that it works more like an ecosystem than a single factory. This is a place where logistics are king. Trains snake into exclusive terminals dropping off Australian and Brazilian iron ore. Ocean freighters tie up to private docks, unloading coal and minerals from five continents. Conveyors as long as football fields carry the ore to berthed blast furnaces.

The process starts with iron ore pellets and coke (sort of purified coal), thrown into monster-sized blast furnaces—some taller than a 20-story apartment block. Temperatures inside go up to 2,000°C. Molten iron pours out the bottom; at the top, the emissions (hot gases, mainly CO₂) are captured or recycled wherever possible. Think of those dramatic sparks and glowing rivers that you see in industrial documentaries—yep, that’s real.

Then, there’s the conversion. Molten iron and scrap steel are mixed inside basic oxygen furnaces, thundering away like mechanical beasts. Here, oxygen is blown in at high speed to burn off impurities. This is where iron takes its final step into becoming raw steel. The freshly-formed hot metal moves to the casting shop, where it’s rapidly cooled and formed into slabs. Next step: rolling mills. These slabs are reheated and squeezed with force that’d flatten a tank, forming paper-thin coils for the auto industry or thick beams for skyscrapers.

Throughout, it’s all about tearing down bottlenecks. Imagine orchestras of robots, sensors, AI-driven systems that can predict a problem before it hits, and thousands of screens controlling just the temperature or carbon mix in one zone. You’ll spot operator control rooms where dozens of engineers monitor giant banks of data feeds. If you’re picturing something old-school and dirty, rethink it—while, sure, it’s rugged and there’s more grit here than at a marathon, it’s also a hotbed for modern automation.

Efficiency isn’t just about high speed. Recycling is a big piece of the picture. In 2024, Baowu reports that up to 38% of its steel comes from recycled scrap, melted in electric arc furnaces right on the premises. Water gets cleaned and reused, and even excess heat is piped to nearby neighborhoods in Shanghai, reducing the need for outside heating in cold months. That innovation saves millions of dollars and cuts down carbon bills, too.

The trickiest challenge? Keeping energy use under control. Steelmaking drinks up about 7% of global energy each year. A good deal of that gets eaten up in these mega-plants. Power bills for a day can soar over $1 million! As a result, Baowu and its competitors have armies of engineers working on how to tap renewable energy, store excess power, and get more bang out of every watt.

One tip for industry watchers: if you want to know where steel prices are heading, keep an eye on Baoshan’s operation reports. When their furnaces slow down or speed up, it ripples through everything from new car launches to bridge construction costs. The plant’s output is so critical that global steel prices can spike if a single furnace goes offline for unexpected repairs.

What Makes These Mega Plants So Important?

The first thing to get is that the biggest steel plant isn’t only about size for pride’s sake. These places hold the keys to the world’s industrialization—without Baoshan and its kin, you wouldn’t have affordable cars, wind turbines, metro lines, or even half the kitchen gadgets that make life modern. Most folks take it for granted, but without the steady hum of steel, entire economies would grind to a halt.

Let’s talk jobs: Baowu alone supports more than 114,000 people across its sites in China, with tens of thousands just at Baoshan. Add the support industries—everything from shipping to machinery repairs—and you get even more jobs in the wider orbit. For a sprawling city like Shanghai, Baoshan is not just an employer but an economic engine. Shops, restaurants, schools, even parks have grown up around the needs of steelworkers and their families.

Here’s a cool tip: If you ever get a chance (some organized tours do run, though get ready for the paperwork!), a steel plant trip will rewire how you look at modern cities. In person, Baoshan’s scale is hard to grasp: the clangor, the radiant heat, and the 24/7 motion. Watch the steel surface cool before your eyes—sometimes you even see the reflection of the city skyline in a sheet that’s barely had time to solidify. It’s a jaw-dropper for anyone, not just industry geeks.

But it’s not just about local clout. The output from Baoshan and other mega plants shapes global infrastructure. During COVID’s supply chain chaos, the world watched steel prices jump by up to 200%, all because a handful of blast furnaces idled for just a few weeks. Mega plants can mean the difference between building something in a year or being stuck in design limbo waiting for supplies.

There’s also a race for cleaner steel, and the leaders, like Baoshan, set standards that even U.S. or European firms watch closely. Innovations tested here often trickle to smaller mills worldwide. Hydrogen-fueled blast furnaces, carbon capture, advanced recycling—they all get their big debuts in plants like this before becoming industry-wide norms.

If you’re new to steel, here’s a fun fact to remember: Every year, enough steel flows out of Baoshan’s gates to build over 60,000 Eiffel Towers, or about 10,000 kilometers of high-speed rail. It’s that scale—steel you can actually measure in cities, not just tons—that makes mega plants so mind-blowing.

For me, as a guy who once watched a bridge replaced in my own hometown (shout-out to Rex, my dog, for being my bridge-walking buddy), seeing the backbone of all that, standing like a city within a city, is still thrilling. Next time you pass by a massive construction site or ride a train, maybe you’ll think of the colossal steel furnaces in Shanghai, burning through the dark, keeping the wheels of our world turning every single day.