Food Profit Margin Calculator

Calculate Your Food Profit Margin

Estimate potential profit margins for different food products based on article insights. Input your cost and selling price to see if you're in the high-margin category.

Why This Matters

The article shows that foods like dried apple rings ($0.20 cost, $4.99 price) achieve 200%+ margins, while fresh baked goods often yield only 30-40%. This calculator helps identify products that maximize profit with minimal waste and storage requirements.

Article Insight: "The most profitable food to sell isn't the fanciest, the most exotic, or the most trendy. It's the one that costs the least to make, lasts the longest, and feels like a treat to the buyer."

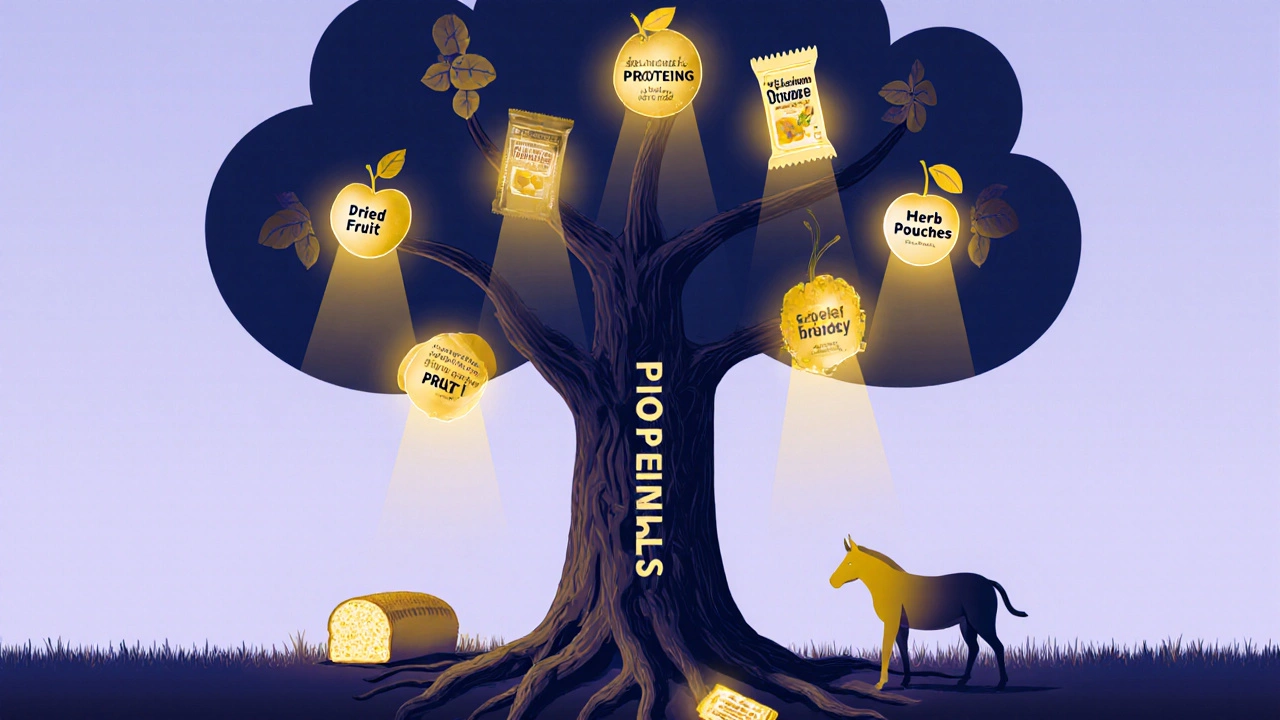

When you’re running a food processing unit, profit isn’t just about volume-it’s about what you make, how much it costs to produce, and how fast it sells. Not all foods are created equal when it comes to margins. Some items cost pennies to make and sell for dollars. Others take hours of labor, expensive ingredients, and complex equipment, yet barely break even. So what’s the most profitable food to sell in 2025? The answer isn’t a single item-it’s a category of products that combine low input cost, high perceived value, long shelf life, and strong consumer demand.

Snack Foods Dominate the Profit Margin Leaderboard

Snack foods are the clear winners. Think roasted nuts, flavored popcorn, protein bars, baked chips, and seasoned pretzels. These aren’t just trendy-they’re engineered for profit. A bag of roasted almonds might cost $1.20 to produce (raw nuts, seasoning, packaging, labor) and sell for $4.99 in a grocery store. That’s a 315% markup. Even in bulk or wholesale, you’re still looking at 150-200% margins.

Why? Because the raw ingredients are cheap, the processing is simple, and the packaging makes it look premium. A 5-pound bag of raw almonds costs about $15 wholesale. After roasting, salting, and putting it in a branded resealable pouch, you’re selling it as a gourmet snack. Consumers don’t think about the cost-they think about convenience, health, and taste. And that’s where the profit hides.

Compare that to selling fresh bread or baked goods. You need daily production, refrigerated storage, short shelf life, and frequent delivery. Even if you sell 200 loaves a day at $4 each, your net margin might be 30-40%. Snacks? You can make a batch once a week, store it for months, and ship it nationwide.

Ready-to-Eat Meal Kits Are Surging

Another rising star: single-serve, shelf-stable meal kits. These aren’t freeze-dried military rations-they’re flavorful, nutritionally balanced meals packed in lightweight pouches. Think curry with basmati rice, chili with cornbread, or teriyaki chicken with quinoa. These are sold in convenience stores, gas stations, and online subscription boxes.

Production costs? Around $1.50 to $2.50 per unit. Retail price? $5.99 to $8.99. That’s a 200-350% markup. The key is using vacuum-sealed, retort-pouched packaging. This technology sterilizes food without refrigeration, giving it a 12-18 month shelf life. You don’t need cold chain logistics. You don’t need daily restocking. One truckload of these pouches can supply hundreds of stores for months.

Branding matters here too. A pouch labeled “Chef-Crafted Thai Coconut Curry” sells better than “Instant Rice Meal.” Even if the ingredients are the same, the story changes the price point. Consumers pay for experience, not just calories.

Dried and Dehydrated Foods Are Underestimated

Dehydrated fruits, vegetables, and herbs are quietly one of the most profitable corners of the food industry. A pound of fresh strawberries costs $3.50. After dehydration, you get about 4 ounces of dried fruit. That 4-ounce bag sells for $6.99. The energy cost to dry them? Less than $0.10 per batch. Labor? Minimal. Packaging? Simple.

And the demand? Growing. Parents buy them for school lunches. Hikers and campers stock them for trips. Fitness enthusiasts use them as clean snacks. They’re naturally gluten-free, vegan, and free of preservatives-no marketing needed.

Even dried herbs and spices can be profitable. Buying rosemary in bulk for $8 per pound, drying it yourself, and selling it in 1-ounce jars for $4.50 each gives you a 500% return. The same applies to garlic powder, chili flakes, and dried mushrooms. These are low-tech, high-margin products that require little space and no refrigeration.

Plant-Based Protein Snacks Are Exploding

Plant-based isn’t just a trend-it’s a profit engine. Soy, pea, and lentil-based protein snacks are seeing 25-30% annual growth in sales. A 1.5-ounce bar made from pea protein, oats, and dates costs under $0.80 to produce. It sells for $3.49 in health stores and $4.99 online.

What makes this even better? You can source protein isolates in bulk from agricultural cooperatives. The ingredients are stable, non-perishable, and scalable. Unlike meat-based snacks, you don’t deal with USDA inspections, animal sourcing volatility, or ethical backlash. The regulatory environment is simpler, and the marketing angle-“clean,” “sustainable,” “vegan”-resonates with younger buyers.

Brands like Perfect Bar and No Cow built empires on this model. You don’t need to be a big company to compete. A small food processor with a dehydrator, a vacuum sealer, and a website can start selling these profitably within weeks.

What to Avoid: Low-Margin, High-Overhead Foods

Not everything that sells is worth making. Stay away from:

- Freshly baked goods-high labor, short shelf life, need daily production

- Ready-to-eat meals with refrigeration-cold chain adds 20-30% to logistics cost

- Raw produce-low margin, perishable, competitive with grocery chains

- Alcohol-infused snacks-legal complexity, licensing, age restrictions

- Custom gourmet chocolates-high ingredient cost, seasonal demand, delicate handling

These items tie up capital, require constant inventory turnover, and leave you vulnerable to waste. If your goal is profitability, focus on products that sit on shelves for months, not days.

Scaling Profit: Packaging, Branding, and Distribution

Even the best product won’t make money if it’s wrapped in a plain white bag and sold at a farmers market. Profit comes from perception and reach.

Use matte-finish pouches with bold typography. Add a QR code that links to a short video of your production process-people trust what they see. List your products on Amazon Handmade, Etsy, and Walmart’s online marketplace. Don’t wait for grocery chains to come to you. Start online, build reviews, then pitch to regional distributors.

Private labeling is another path. Make a batch of spicy roasted chickpeas, then sell them under a local gym’s brand. You handle production. They handle marketing. You keep 70% of the profit. No advertising budget needed.

Real Numbers: What One Small Processor Made Last Year

A small food processor in Ohio started with a $12,000 setup: a dehydrator, vacuum sealer, labeling machine, and a used oven. They focused on three products: roasted pumpkin seeds, dried apple rings, and lentil protein bars.

Monthly costs: $1,800 (ingredients, packaging, utilities)

Monthly sales: $14,500

Net profit: $9,200

They didn’t have a fancy website. They didn’t hire a marketer. They just made good product, sold it on Etsy and at local hiking stores, and let word of mouth do the rest. In 10 months, they paid off their equipment. Now they’re expanding into international markets.

Bottom Line: Profit Lives in Simplicity

The most profitable food to sell isn’t the fanciest, the most exotic, or the most trendy. It’s the one that costs the least to make, lasts the longest, and feels like a treat to the buyer. Snacks, dried goods, and plant-based protein items win because they check every box: low cost, high markup, easy storage, and strong demand.

If you’re starting a food processing unit, don’t chase complexity. Build a few high-margin products. Perfect them. Sell them online. Scale slowly. The money isn’t in making more-it’s in making smarter.

What food has the highest profit margin?

Dried fruits, roasted nuts, and plant-based protein bars have the highest profit margins-often 200% to 500%. These items use low-cost raw ingredients, require minimal processing, and can be packaged for long shelf life. For example, dried apple rings cost under $0.20 to make and sell for $4-$6 per bag.

Is selling snacks more profitable than selling fresh food?

Yes, by a wide margin. Fresh food like bread, dairy, or produce has low margins (10-30%), high spoilage rates, and requires daily restocking. Snacks like roasted chickpeas or protein bars can sit on shelves for 6-12 months with almost zero waste. You make more per unit and spend less on storage and logistics.

Do I need a commercial kitchen to start?

It depends on your state’s cottage food laws. In many U.S. states, you can legally sell low-risk items like dried fruit, roasted nuts, and baked goods from your home kitchen without a commercial permit. Check your local health department rules. For higher-risk items like meat or dairy, you’ll need a licensed facility-but that’s not where the biggest profits are anyway.

What’s the cheapest equipment to start with?

Start with a food dehydrator ($150-$300), a vacuum sealer ($100-$200), and a labeling machine ($50). These let you make dried fruits, herbs, and snacks. You can add a small oven later for baking chips or protein bars. Avoid expensive machinery like extruders or freeze-dryers until you’re making $10k+ per month.

Can I sell food online without a website?

Absolutely. Platforms like Etsy, Amazon Handmade, and Facebook Marketplace let you sell food products without building a website. Many small processors start here, build reviews, and then move to their own site later. Focus on great product photos and clear descriptions-your listings are your storefront.

If you’re thinking about entering the food processing space, skip the flashy ideas. Focus on what’s simple, scalable, and profitable. The market rewards those who make the right product-not the loudest one.