What $1 Can Do in Manufacturing: Unpacking the Impact

Apr 14 2025

When we talk about US manufacturing, the process of making goods in the United States using labor, machinery, and raw materials. Also known as domestic production, it’s no longer just about massive auto plants and steel mills—it’s also about small shops making custom tools, local factories producing medical devices, and startups building electronics in garages. This isn’t a dying industry. It’s changing shape—and becoming more important than ever.

Small scale manufacturing, making products in limited batches with focused resources. Also known as micro-manufacturing, is thriving across America. These businesses don’t compete on volume. They win by speed, customization, and control. Think a workshop in Ohio making specialized metal parts for local farmers, or a team in Oregon producing organic soap in 500-unit runs. They’re not replacing big factories—they’re filling gaps big factories ignore. And when global supply chains broke down during the pandemic, local manufacturing, producing goods close to where they’re used. Also known as onshore production, proved it could keep hospitals stocked, schools supplied, and small businesses running. That’s why government programs now offer grants and tax breaks to bring production back home.

Meanwhile, manufacturing startups, new companies building physical products from scratch. Also known as hardware startups, are popping up everywhere—not just in Silicon Valley, but in rural towns and midsize cities too. They’re not chasing venture capital like software apps. They’re focused on one product, one customer segment, and one profit margin. Many start with under $10,000, using 3D printers, local suppliers, and direct-to-consumer sales. These aren’t fantasy ideas. They’re real businesses turning $1,000 into $100,000 in revenue by making things people actually need.

And it’s not just about making stuff. It’s about making jobs. manufacturing jobs, positions in factories, workshops, and production facilities that build physical goods. Also known as industrial jobs, pay better than most service roles and often come with benefits—especially at small and midsize firms that value loyalty. These aren’t the same old assembly line gigs. Today’s roles involve robotics, quality control software, supply chain tracking, and even design collaboration. You don’t need a four-year degree to start—just the willingness to learn.

What you’ll find in the posts below isn’t theory. It’s real stories: how Indian pharma companies supply half of America’s generic drugs, why Texas dominates plastic production, how India is racing to become an electronics hub, and what small businesses can actually make with $1,000. You’ll see who’s winning, who’s failing, and why the next big thing in manufacturing might not be in a skyscraper—but in a warehouse on the edge of town.

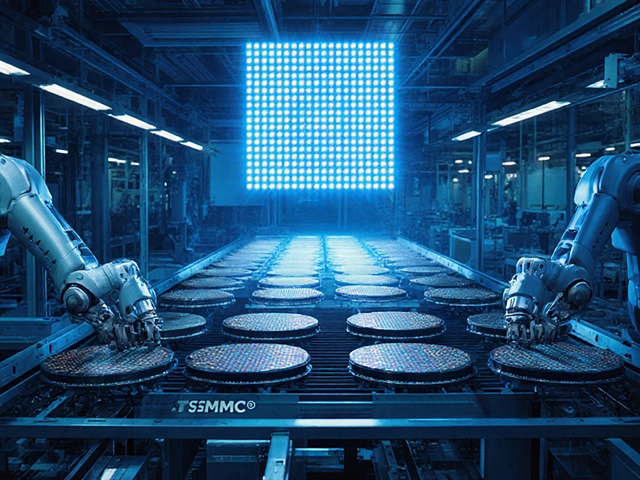

The US is no longer the world's top manufacturer by volume, but it leads in high-value, high-tech production. Government schemes aim to boost semiconductors and clean energy, not just quantity.

The United States is home to hundreds of steel plants, playing a vital role in both local economies and the national manufacturing sector. This article explores the number of steel plants across the US, their distribution, and interesting facts about their operations. With the global demand for steel continuously on the rise, it's fascinating to see how US plants contribute to meeting these needs. Discover the types of facilities and what makes the American steel industry unique.

Apr 14 2025

May 14 2025

Oct 17 2025

May 20 2025

Nov 16 2025