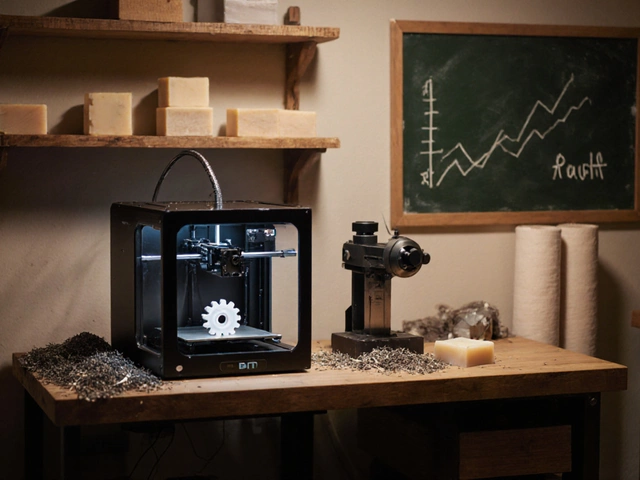

Most Profitable Small‑Scale Manufacturing Products in 2025

Oct 26 2025

When you think of modern steel plants, large-scale industrial facilities that produce steel using advanced technologies like electric arc furnaces and continuous casting. Also known as integrated steel mills, these facilities are the engine behind everything from skyscrapers to electric vehicles. Unlike the old, smoky mills of the 20th century, today’s plants are clean, precise, and data-driven. They don’t just melt scrap metal—they optimize every gram of energy, track every ton of output, and reduce waste like never before.

What makes a modern steel plant, a high-efficiency facility that uses automation, AI monitoring, and recycled materials to produce steel with lower emissions different? It’s not just the size. It’s control. These plants use electric arc furnaces instead of coal-powered blast furnaces in many cases, cutting carbon output by up to 70%. They recycle scrap steel from old cars, appliances, and buildings—turning waste into new beams and rebars. And they don’t rely on guesswork. Sensors monitor temperature, pressure, and composition in real time. If a batch is off by a fraction of a percent, the system adjusts automatically.

India’s push into steel manufacturing, the process of producing steel at scale using advanced machinery, automation, and sustainable inputs isn’t just about meeting demand—it’s about leadership. The country is now the world’s second-largest steel producer, and it’s building new plants faster than almost any nation. Government incentives, cheap renewable power, and a growing construction boom are all fueling this. Companies like Tata Steel and JSW are investing billions not just to make more steel, but to make it smarter. These aren’t just factories—they’re tech hubs with robotic arms, digital twins, and real-time supply chain tracking.

It’s not all about big players, though. Smaller manufacturers are also tapping into this shift. They’re buying used equipment from closed plants, upgrading it with modern controls, and producing niche steel products for local builders. This is where industrial manufacturing, the large-scale production of goods using machinery, automation, and standardized processes meets real-world need. A small brick maker in Rajasthan might not run a steel plant, but he needs high-grade rebar. That rebar comes from a modern plant—maybe one built last year in Odisha or Gujarat.

And here’s the thing: modern steel plants aren’t just about making material. They’re about making resilience. During supply chain chaos, countries that had local steel production didn’t wait for imports. They kept building. India’s push isn’t just economic—it’s strategic. Every new plant reduces reliance on imports, creates skilled jobs, and supports everything from housing to highways.

What you’ll find below isn’t a list of plant specs or corporate brochures. It’s real, practical insight into how manufacturing works today—from the smallest workshops to the biggest industrial complexes. You’ll see how small businesses connect to massive steel production, how India’s growth is reshaping global supply chains, and why the next generation of builders is choosing materials made with precision, not just power.

Explore where the biggest steel plant in the world is located, what makes it massive, the technologies behind its power, and facts about steel production today.

Oct 26 2025

Nov 8 2025

Apr 9 2025

Jul 5 2025

Feb 19 2025