What Is Small Scale Manufacturing? Simple Definition and Real Examples

Nov 8 2025

When you think of filtration, the process of separating solids from liquids or gases to improve purity and performance. Also known as separation technology, it's not just about cleaning water—it's the unseen guard that keeps manufacturing running right. In brick making, dust from clay mixing can ruin product consistency. In pharma, airborne particles can contaminate pills. In food processing, unfiltered water can spoil batches. Filtration isn't optional—it's the baseline for quality control.

Manufacturers don’t just use filters—they design systems around them. water filtration, the removal of impurities from water used in production. Also known as process water treatment, it’s critical for brick plants where water quality affects clay binding and drying time. Poor filtration means uneven bricks, cracks, or weak structures. In electronics manufacturing, even tiny dust particles can short-circuit chips. That’s why cleanrooms use multi-stage air filtration, the process of removing particulates and contaminants from air in controlled environments. Also known as HEPA filtration, it’s the reason India’s growing semiconductor hubs can compete with global players. And it’s not just about machines—filtration includes sediment traps, mesh screens, and even gravity settling tanks in small-scale operations.

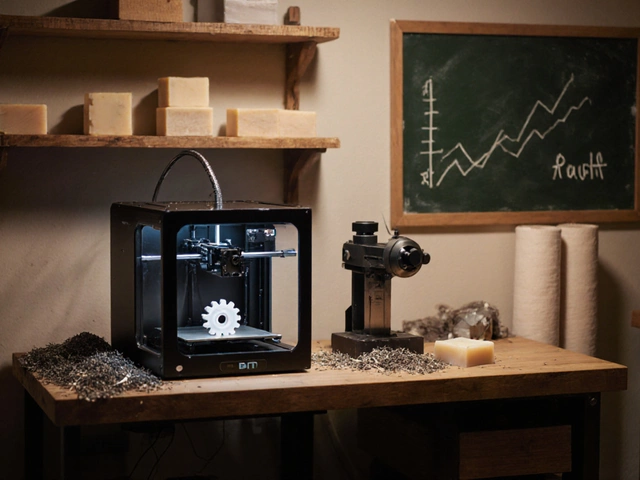

What’s surprising is how often small manufacturers get this right without big budgets. A $1,000 soap-making setup might use a simple cloth filter to strain oils. A local food processor might boil and strain water before mixing ingredients. These aren’t fancy systems, but they’re smart. They know that if the input isn’t clean, the output won’t be either. Filtration cuts waste, reduces returns, and keeps workers safe from harmful dust or fumes.

You’ll find filtration hiding in plain sight across the posts below. From how Indian chemical plants handle wastewater to why Surat’s textile mills need clean air to spin fine yarn, it’s the quiet hero behind every product. Whether you’re running a micro-factory or just starting out, understanding filtration means understanding reliability. Below, you’ll see real examples of how small manufacturers use simple, smart filtration to outperform big competitors—and why that’s the future of local production.

5 μm pops up all the time in food processing, but what does it really mean? This article breaks down microns, especially 5 μm, and shows how tiny things can make a big difference. You'll see where 5 μm fits in with filters and safety, and pick up some simple tips for making sense of food safety specs. Find out how understanding this measurement can help you choose the right gear or check if your processes are tight enough. Get ready to see food processing through a sharper lens.

Nov 8 2025

Feb 26 2025

Apr 14 2025

Oct 26 2025

Oct 9 2025