Profitability Calculator

Find Your Profitable Manufacturing Product

Calculate which product niche offers the best fit for your workshop based on your budget, space, skills, and target market.

Your Best Manufacturing Opportunity

Recommended Product:

| Product | Score | Margin | Startup Cost | Match |

|---|

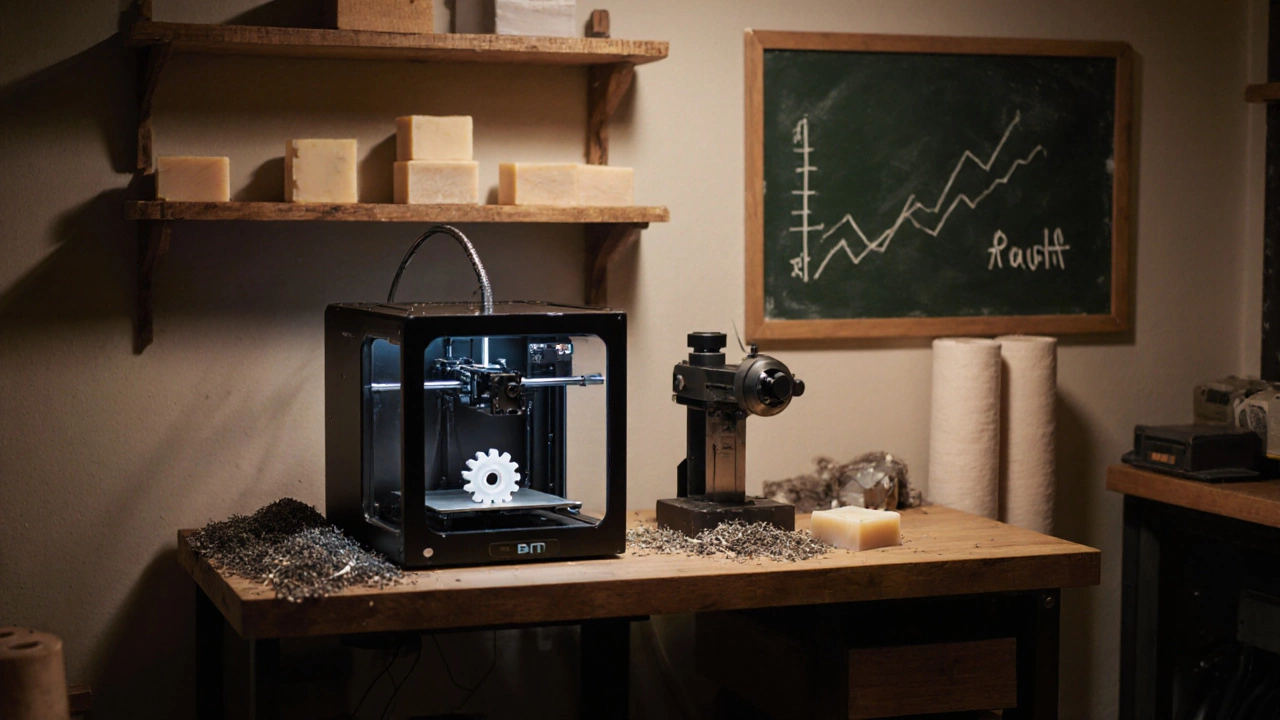

Ever wondered which product can turn a modest workshop into a cash‑generating machine? In 2025 the answer isn’t a single gadget but a handful of niches where margins soar, startup costs stay low, and demand keeps rising. Below you’ll find a step‑by‑step roadmap to spot the most profitable manufacturing product for your situation, plus real‑world examples you can copy today.

Understanding Profitability in Small‑Scale Manufacturing

Small Scale Manufacturing is a production approach that uses limited capital, a compact workspace, and often a blend of manual and digital tools to create niche goods for specific markets. When you compare options, focus on four hard numbers:

- Gross profit margin - revenue left after material costs.

- Startup investment - equipment, tooling, and initial inventory.

- Market demand - how many buyers are actively searching.

- Skill threshold - does the product need years of expertise?

Plugging these into a simple spreadsheet lets you rank ideas quickly.

Top High‑Margin Product Niches for 2025

Below are six product families that consistently beat the 30% margin benchmark while staying affordable for a starter shop.

- 3D‑Printed Custom Parts are small‑batch components for hobbyists, drone builders, and replacement parts. The material cost per gram is under $0.10, yet you can charge $15‑$30 for a design.

- CNC‑Machined Metal Fixtures serve labs and makerspaces. A modest CNC mill costs $3,000-$5,000, but precision parts fetch $50‑$120 each.

- Custom Printed Circuit Boards (PCBs) for low‑volume electronics startups. Prototype boards run $20‑$40 and can be sold for $80‑$150.

- Eco‑Friendly Packaging made from biodegradable films or recycled cardboard. Brands pay a premium for sustainable packaging-often $0.30 extra per unit.

- Handmade Natural Soap blends essential oils and local botanicals. Production cost is roughly $0.50 per bar, while boutique retailers list them at $4‑$7.

- Plant‑Based Snack Bars cater to the growing vegan market. With bulk oats, nuts, and fruit, a bar costs $0.35 to make, but stores price them $2.50‑$3.50.

Each of these ideas fits a different skill set, but all share the common thread of high margin and scalable demand.

Quick Comparison of Profit Drivers

| Product | Avg. Gross Margin | Typical Startup Cost | Market Demand (units/yr) | Skill Level |

|---|---|---|---|---|

| 3D‑Printed Custom Parts | 45 % | £2,500‑£4,000 (printer + software) | 10‑20 k | Basic CAD |

| CNC‑Machined Fixtures | 38 % | £3,000‑£5,500 (mill) | 5‑12 k | Intermediate machining |

| Custom PCBs | 42 % | £1,200‑£2,000 (fab printer) | 3‑8 k | Basic electronics |

| Eco‑Friendly Packaging | 33 % | £1,000‑£2,500 (die‑cut tools) | 15‑30 k | Low |

| Handmade Soap | 50 % | £500‑£1,200 (molds, oils) | 8‑15 k | Low |

| Plant‑Based Snack Bars | 44 % | £800‑£1,500 (mixing & packaging) | 12‑25 k | Low‑Medium |

The table shows why a low‑skill, low‑cost entry like soap can compete with a higher‑skill CNC shop-profits depend on how you position yourself in the market.

How to Choose the Right Product for Your Workshop

Match the four profitability factors against your personal constraints:

- Budget: If you have under £3,000, start with soap or snack bars.

- Space: 3D printers and soap molds need a small bench; CNC mills demand a dedicated floor area.

- Skill set: Leverage any existing design or culinary expertise instead of learning a completely new trade.

- Target market: Look for local retailers, online marketplaces (Etsy, Amazon), or niche B2B buyers (labs, eco‑brands).

Run a quick “profit‑fit” matrix: assign 1‑5 points for each factor, add them up, and the highest score points to your best bet.

Step‑by‑Step Blueprint to Launch Your Product

- Validate demand: Use Google Trends, keyword tools, and competitor analysis on platforms like Etsy to confirm at least 1,000 monthly searches.

- Prototype cheaply: For soap, make a batch of 30 bars; for PCBs, order a low‑volume run of 5 prototypes.

- Cost out: List material, labor (your time), and overhead. Aim for a margin above 30%.

- Secure a first sale: Offer a limited‑time discount to a local retailer or launch a Kickstarter campaign.

- Refine and scale: Re‑invest profits into better equipment (e.g., upgrade to a dual‑extruder 3D printer) and expand your product line.

This loop repeats until you hit a stable cash flow-usually after 3‑6 months of steady orders.

Common Pitfalls and Pro Tips

Even the most profitable ideas can stumble. Here are three traps and how to avoid them:

- Over‑engineering: Adding unnecessary features inflates cost and erodes margins. Stick to the core benefit.

- Ignoring regulations: Soap and food bars must meet UK health standards. Register with the MHRA for cosmetics or the Food Standards Agency for snacks before you sell.

- Poor pricing strategy: Undercutting competitors may seem smart, but it signals low quality. Use a “value‑based” price that reflects the premium you deliver.

Pro tip: Keep a simple spreadsheet of each batch’s costs and revenues. Review it weekly to spot margin drift before it becomes a problem.

Mini FAQ - Quick Answers to Your Burning Questions

Which product needs the smallest upfront investment?

Handmade natural soap typically requires under £1,000 for molds, oils, and basic safety equipment, making it the cheapest entry point.

Do I need a business licence to sell custom PCBs?

In the UK you need to register as a limited company or sole trader and ensure the PCBs meet the CE marking requirements. No specific licence beyond standard trading registration is required.

Can I sell eco‑friendly packaging without any certifications?

While certifications like FSC or compostability logos boost credibility, you can start by using certified raw material suppliers and clearly stating your sustainability claims.

What’s the best online platform to launch a small‑scale food product?

For UK sellers, the combination of a Shopify store + Amazon UK FBA provides both brand control and massive reach. Etsy works well for niche, artisanal batches.

How long does it take to break even on a CNC mill?

Assuming a £4,500 mill, 20% monthly overhead, and a 40% margin on parts sold at £80 each, most operators see break‑even after 8‑10 months of steady orders.

Got more questions? Jump into the comments or start a quick market test- the data will tell you fast.