Manufacturing Startup Survival Calculator

Based on UK Business Finance data (2024), only 12% of manufacturing startups survive past 5 years. This calculator shows your personalized odds of building real wealth based on key business factors.

People talk about startup founders becoming millionaires overnight. You hear stories of someone building a app in their garage and selling it for hundreds of millions. But what if you’re not building an app? What if you’re starting a manufacturing business - the kind with machines, factories, raw materials, and workers? Can you get rich from that?

The short answer: yes. But not like the movies. Not fast. Not easy. And not for most people.

Manufacturing Startups Are Harder Than You Think

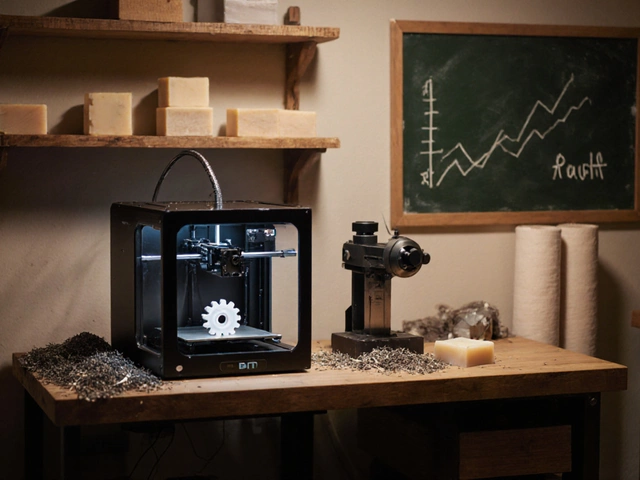

Most people assume startups are about ideas. The truth? In manufacturing, your idea is just the starting line. You need capital to buy presses, molds, CNC machines, or assembly lines. You need space - real, zoned industrial space. You need permits. You need to hire skilled operators. You need to source reliable suppliers. And you need to sell to customers who don’t care about your story - they care about price, quality, and delivery time.

A friend in Liverpool started a small batch metal fabrication shop in 2022. He had a $150,000 loan, two welders, and a dream. Two years later, he’s making $80,000 a year in profit. Not bad. But he hasn’t slept through a night without checking machine logs since day one. He didn’t get rich. He got stable. And that’s the reality for 80% of manufacturing startups.

Who Actually Gets Rich?

There are winners. But they’re not the ones you think.

Take the founder of a company that makes custom plastic components for medical devices. He started in a 2,000-square-foot unit in Stoke-on-Trent. He didn’t invent anything new. He just got better at one thing: consistency. His molds never failed. His tolerances were tighter than anyone else’s. He built relationships with three big NHS suppliers. By year five, he was selling 12 million parts a year. He sold the company for $42 million in 2024.

His secret? He didn’t chase hype. He didn’t pitch investors. He didn’t hire a fancy marketing team. He showed up every day, fixed the machines, trained his team, and delivered on time. He got rich because he mastered a niche so small, no one else wanted to bother with it.

That’s the pattern. The richest manufacturing founders aren’t the loudest. They’re the quiet ones who solve boring problems better than anyone else.

The Numbers Don’t Lie

According to UK Business Finance data from 2024, only 12% of manufacturing startups survive past five years. Of those, only 3% reach annual revenues over £2 million. And of that 3%, maybe one in ten ends up with an exit worth more than £10 million.

That means if you start a manufacturing business today, your odds of becoming truly wealthy - say, £10M+ - are less than 0.3%. That’s lower than winning the lottery.

But here’s what most people miss: you don’t need to sell the company to get rich. You can build wealth slowly by reinvesting profits. One metal casting business in Birmingham started in 2018 with £50,000. They didn’t take outside money. They reinvested every pound back into the business. By 2023, they owned three machines, employed 11 people, and pulled in £1.4 million in revenue. The owner took home £320,000 in salary and dividends. He’s not a billionaire. But he owns his home, his car, his workshop, and his freedom. That’s wealth too.

What Actually Works in Manufacturing Startups?

If you want to build real value - not just a flashy pitch deck - here’s what you need to focus on:

- Niche specialization: Don’t make "everything." Make one thing, really well. Think: custom brass fittings for marine engines. Or silicone seals for food-grade mixers. Tiny markets with high barriers to entry.

- Process control: The best manufacturing businesses aren’t the ones with the fanciest machines - they’re the ones with the tightest quality control. Document every step. Train your team to spot defects before they happen.

- Local supply chains: If you’re in the UK, source materials from British suppliers. It’s slower, sometimes pricier, but you avoid customs delays, currency swings, and shipping disasters. One ceramics maker in Derby cut lead times from 14 weeks to 3 weeks by switching to local clay suppliers.

- Customer lock-in: Build relationships with clients who can’t easily switch. If your product is part of their compliance certification (like food safety or medical standards), they’ll stick with you even if you’re 10% more expensive.

These aren’t flashy strategies. But they’re the ones that compound over time.

Why Most Manufacturing Startups Fail

Let’s be honest. Most people who start manufacturing businesses don’t understand the grind.

They think: "I’ll make cool stuff, sell it online, and scale fast." But manufacturing doesn’t scale like software. You can’t copy a machine. You can’t push an update. If a machine breaks, production stops. If a supplier delays raw material, you miss deadlines. If a worker quits, you lose institutional knowledge.

Here’s what kills most startups:

- Underestimating startup costs - many think £50k is enough. It’s not. You need at least £200k to start properly.

- Overestimating demand - they build 1,000 units and only sell 150.

- Ignoring cash flow - they spend on new machines before they’ve paid their first invoice.

- Trying to compete on price - you can’t win a price war against China. You win by being more reliable, more precise, or more responsive.

One guy in Nottingham spent £180,000 on a 3D metal printer because he thought it was the future. He couldn’t find customers who needed it. He sold it for £40,000 two years later. He’s still paying off the debt.

Realistic Paths to Wealth

Forget the lottery. Think in decades, not months.

Path 1: The Slow Build

Start small. Focus on one customer. Deliver perfectly. Reinvest profits. Grow one machine at a time. By year 10, you own a profitable, debt-free business worth £1.5M-£3M. You’re not a billionaire, but you’re free. No boss. No commute. No fear of layoffs.

Path 2: The Acquisition Play

Build a business that solves a real problem for a bigger company. Get noticed. Get acquired. This works best if you’re supplying parts to a larger manufacturer. They buy you not because you’re sexy - but because you’re reliable. You walk away with £5M-£10M after taxes.

Path 3: The Licensing Model

You invent a unique tool, fixture, or process. You don’t make the product yourself. You license the design to 5-10 manufacturers. You earn royalties. One engineer in Sheffield patented a jig for assembling electric motor housings. He doesn’t run a factory. He gets £12,000 a month just for letting others use his design.

Is It Worth It?

If you want to get rich fast - don’t start a manufacturing business. Go into tech. Go into crypto. Go into real estate flipping. Those are the games where money moves fast.

If you want to build something lasting - something that outlives trends, algorithms, and market crashes - then manufacturing is one of the few places left where real value is still made by hand, by machine, and by sweat.

You won’t wake up a millionaire. But if you stick with it, you might wake up one day and realize you’ve built a life that no algorithm can replace. And that’s worth more than any exit.

What to Do Next

If you’re serious, here’s your first step: don’t buy equipment yet. Don’t rent a factory. Don’t file for a patent.

Go talk to five manufacturers who’ve been around for 10+ years. Ask them: "What’s the one thing I’m not thinking about?" Listen. Write it down. Then do it again with five more.

Most people skip this. They jump straight to the tools. The real work starts before you even touch a wrench.

Can you get rich from a small manufacturing startup?

Yes, but not quickly or easily. Most manufacturing founders build wealth slowly over 10-15 years by reinvesting profits, mastering a niche, and avoiding debt. Only a small fraction become millionaires through exits. The majority build stable, profitable businesses that provide financial freedom without massive wealth.

What’s the success rate for manufacturing startups in the UK?

According to UK Business Finance data from 2024, only 12% of manufacturing startups survive past five years. Of those, just 3% reach annual revenues over £2 million. The chance of building a business worth £10 million or more is less than 0.3%.

Do I need investors to succeed in manufacturing?

No. Many successful manufacturers never took outside money. They used personal savings, bank loans, and reinvested profits. Investors often push for fast growth, which can lead to overexpansion. Bootstrapping lets you grow at your own pace and keep full control.

What manufacturing niches are most profitable right now?

The most profitable niches are those with high barriers to entry and low competition: custom medical components, food-safe seals, specialized tooling for automation, and replacement parts for aging industrial equipment. These markets value reliability over price and are less sensitive to global supply chain shifts.

Is it better to start small or go big with manufacturing?

Start small. Most failures happen because founders spend too much too soon. Begin with one machine, one product, and one customer. Prove you can deliver consistently. Then expand. A £50,000 startup with tight control beats a £500,000 startup with messy operations every time.