When people ask which country makes the best furniture, they’re often thinking of Italy, Sweden, or Denmark. But if you’ve ever sat on a solid teak chair from Rajasthan or run your hand over a carved sheesham dining table from Punjab, you know there’s another player rising fast: India.

India’s Furniture Industry Isn’t Just Big-It’s Brilliant

India doesn’t just make furniture. It builds heirlooms. The country produces over $50 billion worth of furniture annually, with exports hitting $7.2 billion in 2024 alone. That’s up 22% from 2020. And it’s not just volume-it’s quality. Indian craftsmen have been carving wood for centuries, passing down techniques through generations. You won’t find this kind of detail in mass-produced flat-pack furniture.

Take the hand-carved jharokha panels from Jaipur. These are intricate latticework designs originally used in palaces, now adapted for modern wardrobes and headboards. Each panel takes a single artisan 3 to 5 days to complete. No CNC machine can replicate the slight imperfections that give these pieces soul. That’s why luxury hotels in Dubai, London, and New York are sourcing Indian furniture directly.

Why Indian Wood Is Different

Not all wood is the same. India grows some of the densest, most durable hardwoods in the world. Teak from Madhya Pradesh has natural oils that repel termites and resist rot-even in humid climates. Sheesham (Indian rosewood) has a rich grain that darkens beautifully with age. Mango wood, once considered waste after fruit harvests, is now turned into sleek, modern tables with a story behind every knot.

Compare that to Scandinavian pine, which is light and easy to work with but needs chemical treatments to last. Or Chinese particleboard, which is cheap but falls apart after a few years. Indian furniture uses solid wood-no veneers, no MDF, no glue-heavy joints. The joinery? Mortise and tenon. Dovetail. Tongue and groove. The same techniques used in 18th-century English cabinetry.

Handmade vs. Machine-Made: The Real Difference

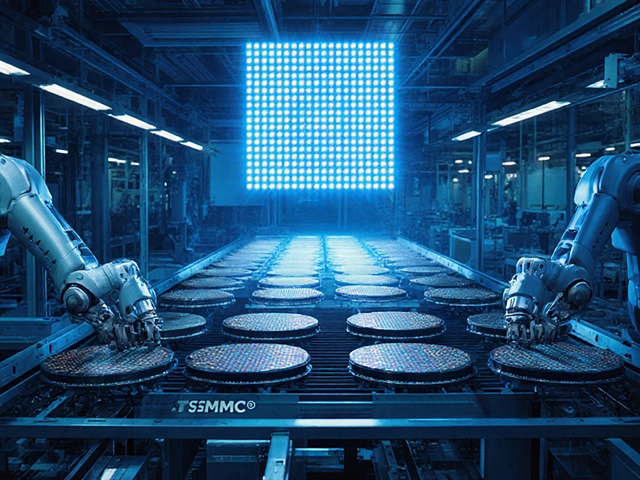

Most furniture you buy today is made in factories with robots. India still has over 1.2 million small workshops-many run by families in villages near Agra, Moradabad, and Ludhiana. These aren’t factories. They’re studios. One craftsman might spend weeks on a single bed frame, sanding by hand, staining with natural oils, and polishing with cloth.

Here’s what that looks like in practice: A customer orders a 6-seater dining table from a workshop in Bareilly. The wood is sourced locally, dried for 8 months to prevent warping, then carved with traditional motifs. The legs are shaped using hand planes, not laser cutters. The finish? A blend of beeswax and linseed oil, applied by hand over three days. The result? A table that lasts 50+ years. And it costs less than a comparable mass-produced piece from IKEA.

Price vs. Value: What You’re Really Paying For

Yes, Indian furniture can be cheaper than European brands. But it’s not cheap because it’s low quality-it’s affordable because labor costs are lower, and there’s no markup from global retail chains. A hand-carved teak sideboard from India might cost $800. The same design from a Swedish brand? $2,500. The difference isn’t in materials-it’s in branding and distribution.

And here’s the kicker: Indian manufacturers are now offering warranties of 10 to 25 years. That’s longer than most U.S. and EU brands. Why? Because they know their furniture won’t break. They’ve seen grandparents pass down pieces to grandchildren. They’re not selling disposable furniture. They’re selling legacy.

Environmental and Ethical Edge

India’s furniture industry is one of the most sustainable in the world. Most workshops use reclaimed wood, fallen trees, or fast-growing species like mango and acacia. No rainforest timber. No illegal logging. Many factories run on solar power now, thanks to government incentives under the Make in India initiative.

Workers are paid fairly. In fact, many artisans earn more than factory workers in other countries because they’re paid per piece, not per hour. A skilled carver can make $15-$25 a day-enough to support a family and send kids to school. No sweatshops. No child labor. The industry is regulated under the Handicrafts and Handlooms Export Corporation, which audits exporters for ethical practices.

Who’s Buying Indian Furniture-and Why

It’s not just expats or luxury buyers. Middle-class families in the U.S., Canada, and Australia are switching to Indian furniture because they want something real. A 2024 survey by the International Furniture Federation found that 68% of buyers in North America now prioritize craftsmanship over brand names. And 72% said they’d pay more for furniture made by hand.

Architects and interior designers are leading the trend. Firms like Gensler and HOK now specify Indian-made pieces in high-end residential projects. Why? Because the textures, the grain, the weight-it all feels different. You can’t fake authenticity.

What to Look For When Buying Indian Furniture

Not every piece labeled "Indian" is worth it. Here’s how to spot the real deal:

- Check the wood-it should feel heavy and solid. Tap it. It should sound dense, not hollow.

- Look at the joints-no screws or nails visible on the outside. Real joinery is hidden.

- Ask about the finish-natural oils and waxes are better than glossy lacquers. Lacquer cracks. Oil deepens with age.

- See the maker’s mark-reputable workshops stamp their name or logo on the underside.

- Ask for wood origin-teak from Madhya Pradesh, sheesham from Punjab, mango from Uttar Pradesh. These are quality indicators.

Avoid anything that says "Indian design" but is made in China. That’s just a label. Real Indian furniture comes from small workshops, not export factories.

The Future Is Solid Wood

The global furniture market is shifting. People are tired of buying things that break. They want things that last. India is perfectly positioned to lead this change. With climate-conscious buyers, rising demand for handmade goods, and a workforce that takes pride in its craft, Indian furniture isn’t just competing-it’s redefining what "best" means.

You don’t need to fly to Delhi to find it. Online platforms like Artisanal India, Utsav Fabrics, and even Etsy now connect buyers directly with workshops. You can order a custom dining table from a village in Rajasthan and have it delivered to your home in Toronto or Berlin-with tracking, insurance, and a lifetime care guide.

The best furniture isn’t made in a country because it has the most factories. It’s made where people still believe in making things right. And right now, that place is India.

Is Indian furniture really better than European furniture?

It’s not about being "better"-it’s about different values. European furniture often focuses on minimalist design and industrial efficiency. Indian furniture focuses on craftsmanship, durability, and natural materials. If you want something that lasts 50+ years with hand-carved details, Indian furniture wins. If you want sleek, modular, and affordable, European brands like IKEA or HAY are better. But when it comes to longevity and artistry, Indian pieces hold their value-and their beauty-over time.

Are Indian furniture exports reliable?

Yes. India has one of the most organized furniture export systems in the developing world. The Wood Furniture Export Promotion Council (WFEPC) certifies exporters, and many factories follow ISO 9001 quality standards. Shipping is handled by major logistics firms like DHL and Maersk. Delivery times are typically 6-10 weeks, and most reputable sellers offer full insurance and return policies. You’re not taking a risk-you’re investing in a proven supply chain.

Can I get custom designs from Indian manufacturers?

Absolutely. Most Indian workshops specialize in customization. You can choose the wood type, size, finish, carving pattern, and even add family initials or religious motifs. Many sellers offer 3D renderings before production. A custom teak bed with carved elephants can take 8-12 weeks, but you’ll own something no one else has. This level of personalization is rare in mass-market furniture.

Is Indian furniture expensive to ship internationally?

Shipping costs depend on size and destination, but Indian furniture is often cheaper to ship than you think. Solid wood is dense, so it’s heavy-but because it’s made without packaging foam or cardboard boxes, the volume is smaller. Many exporters use wooden crates that double as part of the product’s protection. Shipping a dining set from India to the U.S. typically costs $300-$600, which is less than buying a new set locally. Some sellers include shipping in the price.

How do I care for Indian wooden furniture?

Keep it away from direct sunlight and dry heat. Wipe with a slightly damp cloth monthly. Every 6 months, apply a thin coat of beeswax or linseed oil with a soft cloth. Don’t use chemical cleaners-they strip the natural finish. With basic care, your Indian furniture will darken beautifully and last generations. Many owners say their pieces look better after 20 years than when they bought them.

If you’re looking for furniture that tells a story, feels substantial, and lasts longer than your car, stop comparing price tags. Look at the maker. Look at the wood. Look at the hands that shaped it. That’s where the real value lies.