Why Ford and GM Couldn't Make It in India

Apr 4 2025

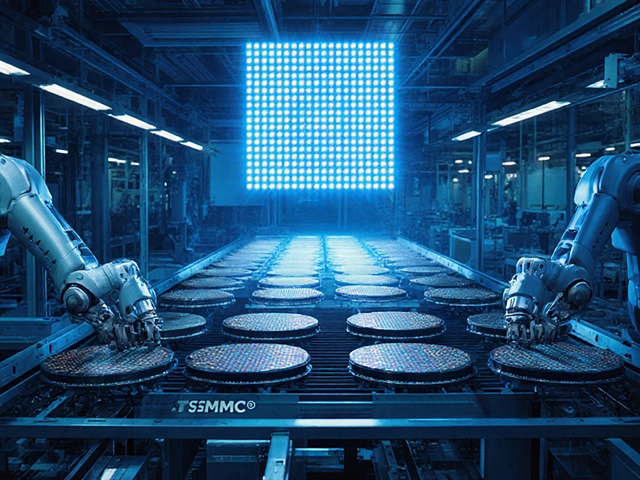

When you think of automotive manufacturing, the process of designing, assembling, and producing vehicles at scale. Also known as vehicle manufacturing, it’s not just about putting parts together—it’s a high-speed dance of robotics, supply chains, and precision engineering that moves millions of cars off assembly lines every year. This isn’t the factory scene from 30 years ago. Today’s plants use AI-driven quality checks, laser-guided welding, and real-time data to cut waste and boost output. And while Germany and Japan built the modern auto industry, India, a fast-growing hub for car and parts production is now racing to catch up, thanks to government incentives and rising local demand.

Behind every car is a web of smaller players: component suppliers, companies that make everything from seat belts to brake pads, and electronic systems integrators, firms that handle the wiring, sensors, and software powering modern vehicles. These aren’t just supporting acts—they’re the reason electric vehicles can now self-diagnose problems or adjust traction on icy roads. The shift to EVs has turned traditional manufacturing on its head. No more internal combustion engines means fewer moving parts, but more batteries, power electronics, and software code. That’s why companies like Tata and Mahindra are investing heavily in battery plants and software teams, not just assembly lines.

What’s surprising? You don’t need a billion-dollar plant to be part of this industry. Many small manufacturers in India make high-quality auto parts for global brands—brackets, hoses, sensors—all built with the same precision as big-name suppliers. These shops thrive because they’re agile, local, and focused on niche products that big factories ignore. And with global supply chains still shaky, automakers are pulling production closer to home. That’s why local manufacturing, bringing production back to where the demand is isn’t just a trend—it’s becoming the new standard.

Whether you’re curious about how your car gets built, wondering why EVs are cheaper to maintain, or thinking about starting a small auto parts business, the posts below cover it all. You’ll find real breakdowns of production lines, profiles of top Indian auto suppliers, and even how startups are breaking into this billion-dollar world with nothing but a prototype and a plan.

Explore why Chevrolet left India, covering market challenges, policy impacts, financial losses, and the ripple effects on the Indian auto sector.

Apr 4 2025

Apr 9 2025

Jul 12 2025

Nov 16 2025

Jun 3 2025