When you hear the phrase small scale industries, you might picture a cramped workshop or a one‑person operation. In reality, these sectors pack big potential into tiny footprints. Below we break down the tiniest manufacturing niches, what they need to get started, and why they’re booming in 2025.

Defining Small Scale Industries

Small scale industries are manufacturing activities that operate with minimal capital, a handful of employees (often fewer than five), and a production volume measured in dozens or low hundreds per month. They typically serve local or niche markets and rely on flexible, manual or lightly‑automated processes. Because they can adapt quickly, these industries thrive on emerging trends, custom orders, and sustainability credentials.

Why Tiny Sectors Matter

Governments, especially in the UK, are pouring funds into micro‑businesses to boost employment and innovation. A 2024 UK Department for Business report shows that micro‑manufacturers contribute £12bn to the economy and create 250000 jobs, many in regions that need revitalisation. For entrepreneurs, the low entry barrier means you can test a product idea without drowning in debt.

Top Ten Smallest Scale Industries in 2025

Below is a quick snapshot of the industries that require the least space, capital, and staff. Each entry includes the typical startup cost, essential equipment, and a real‑world example.

- Cottage industry: Hand‑crafted goods made at home-think pottery, wooden toys, or crochet accessories. Startup cost: £1000-£3000 for tools and raw material. Example: A Liverpool‑based potter selling through Etsy.

- Artisanal food production: Small batches of jam, cheese, or baked goods. Needed: kitchen space, food‑safety certification, and a commercial oven. Startup cost: £2500-£5000. Example: Hand‑crafted sourdough loaves sold at farmers’ markets.

- Handmade textiles: Loom‑woven scarves, up‑cycled denim, or embroidered home décor. Equipment: portable loom or sewing machine. Startup cost: £1200-£2800.

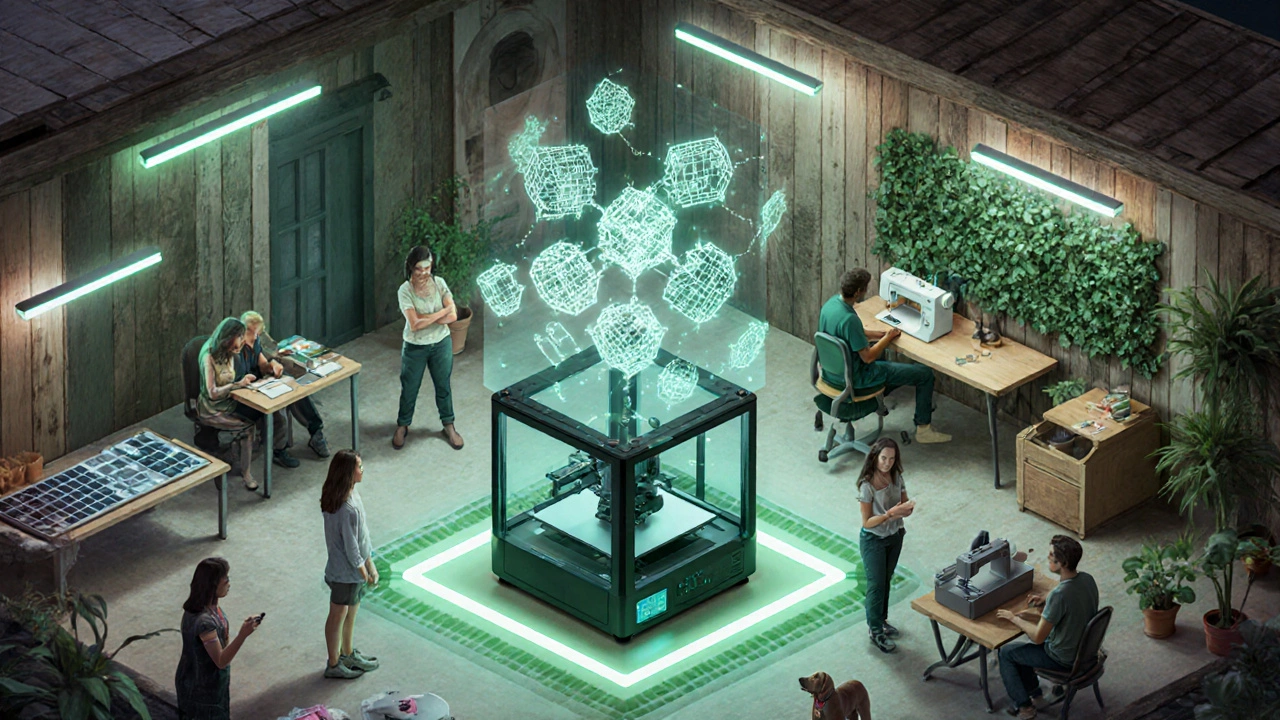

- 3D printing services: On‑demand prototyping or custom figurines. Equipment: a desktop resin printer and design software. Startup cost: £1500-£4000.

- Custom jewellery: Hand‑set stones, laser‑cut metal, or polymer clay pieces. Equipment: bench‑top torch, small lathe. Startup cost: £2000-£6000.

- Boutique cosmetics: Small‑batch soaps, candles, or natural skincare. Required: lab‑grade mixers, compliance testing. Startup cost: £3000-£7000.

- Eco‑friendly cleaning products: Plant‑based detergents or refill stations. Equipment: mixing tanks, bottling line (manual). Startup cost: £2500-£5500.

- Local renewable energy components: Assembling small solar kit boxes or DIY wind‑turbine parts. Equipment: basic soldering station, CNC mini‑router. Startup cost: £4000-£8000.

- Micro‑electronics repair: Fixing smartphones, drones, or wearables. Needed: ESD‑safe workbench and test equipment. Startup cost: £1800-£3500.

- Specialty pet accessories: Handmade collars, biodegradable toys, or custom pet beds. Equipment: sewing machine, fabric cutter. Startup cost: £1200-£3000.

Comparison of Key Attributes

| Industry | Typical Startup Cost (GBP) | Employees Needed | Typical Production Volume | Primary Sales Channel |

|---|---|---|---|---|

| Cottage industry | £1‑3k | 1‑2 | Dozens/month | Online marketplaces |

| Artisanal food | £2.5‑5k | 1‑3 | 100‑300 units | Farmers' markets |

| 3D printing services | £1.5‑4k | 1‑2 | Variable (per order) | Custom orders via website |

| Boutique cosmetics | £3‑7k | 2‑4 | 200‑500 units | Social media shop |

| Local renewable energy components | £4‑8k | 2‑3 | 50‑150 kits | DIY community sites |

Getting Started: A Step‑by‑Step Checklist

- Identify a niche problem or trend you’re passionate about.

- Validate demand with a simple landing page or pre‑order campaign.

- Calculate total initial outlay (equipment, raw material, certification).

- Secure funding - many micro‑manufacturers qualify for UK’s Start‑up Grants (up to £5k).

- Set up a compliant workspace - a garage, a rented loft, or a shared maker space.

- Source suppliers who can deliver small batches at reasonable prices.

- Launch a minimal viable product (MVP) and collect feedback.

- Iterate, refine branding, and scale production gradually.

Common Pitfalls and How to Avoid Them

- Under‑estimating regulatory requirements. Food, cosmetics, and renewable components all need specific safety certifications. Start the paperwork early.

- Over‑investing in equipment. Rent or borrow a 3‑D printer before buying a high‑end model.

- Ignoring cash‑flow timing. Small batch orders can create spikes in material costs. Keep a buffer of at least 15% of projected expenses.

- Relying solely on one sales channel. Diversify; combine online sales with local pop‑ups.

Future Outlook: What’s Next for Tiny Manufacturing?

Four trends are shaping the next wave of micro‑production:

- Distributed manufacturing networks. Platforms like MakerShift let tiny makers share excess capacity, turning idle machines into revenue streams.

- AI‑driven design tools. Generative design software can create printable models in seconds, lowering the skill barrier for 3‑D printing services.

- Sustainable sourcing. Consumers increasingly demand locally sourced raw material, giving an edge to makers who source from regional farms or recyclers.

- Regulatory incentives. The UK’s 2025 “Green Micro‑Manufacturing Fund” offers up to £10k for projects that reduce carbon footprints.

Whether you’re a hobbyist looking to earn extra cash or an aspiring entrepreneur ready to build a brand, the smallest scale industries offer a low‑risk entry point into manufacturing. Pick a niche, follow the checklist, and let the market decide.

Frequently Asked Questions

What capital is needed to start a cottage industry?

You can launch with as little as £1000 if you already own basic tools. Most beginners spend £1500‑£3000 on a quality workbench, hand tools, and initial raw material.

Do I need a special licence to sell homemade soaps?

In the UK, yes. You must register with your local council as a “specialist manufacturer” and comply with the Cosmetic Products Regulation (EU)1223/2009. The process usually costs £150‑£300.

Can a 3‑D printer be used for food‑grade items?

Only printers certified as food‑safe can be used for that purpose. Look for models with stainless‑steel nozzles and detachable, dishwasher‑safe build plates.

How long does it take to get a food safety certification?

Typically 4‑6 weeks, assuming you have a clean workspace and proper documentation ready for the inspector.

What’s the best sales channel for handmade jewellery?

Instagram and Etsy remain top platforms. Combine them with pop‑up stalls at local arts festivals to build a loyal following.